FUNC Function

1. The automatic zooming tracking camera system is installed above the grab bucket which can automatically track the grab lifting all the time. It help the operator to visually inspect the visual blind zone in the operation area, providing accurate and clear video images of the operation area, eliminating the operator’s blind spots and improving the production safety and work efficiency.

2. The IR Speed Dome is installed in the hoisting machine room, which is mainly used to observe the steel wire rope drum. It can avoid the de-grooving of the steel wire rope during the operation of the Ship Unloader Crane which is caused by the luffing and the switching between the heavy load and the no load. And monitor the personnel who is entering the area of the hoisting machine room to improve the safety of the operation.

3. The Integrated Special Camera System is installed at the forefront of the boom to observe the material storage in the cabin and the overall condition of the ship. The mechanical structure can meet the require of the installation stability of the boom in the luffing stage, and eliminate problem caused by the imbalance of force such as the failure of the transmission mechanism, the high falling of the camera system.

4. Receive the digital video streams of cameras through the network, and store and manage it. The multiple network cameras can be watched, browsed, played back, managed and stored at the same time.

5. The recording files can be backed up locally through the mobile storage device. The video image of the local camera system on the Ship Unloader Crane can remotely view, control and download through wired devices (such as optical cable, etc.) or wireless devices (such as wifi, 4G, etc.). Different user levels can be set remotely through wired devices (such as optical cable, etc.) or wireless devices (such as WIFI, 4G, etc.).

6. Single screen switching, multi-screen switching, zoom±, Pan/Tilt, wiper on/off , light on/off and other operations can be realized.

7. The monitor is equipped with Monitor Stability Support Device which has a variety of installation forms such as vertical mounts, corner mounts, wall-hanging mounts and pendant mounts, etc., all of which can achieve all-round angle adjustment.

8. The remote control function can be realized. With the rapid development of China's industrial control automation and intelligent technology in recent years, the intelligent technology of the monitoring industry has also made great progress and has gradually merged with other industrial fields. The degree of automation of the monitoring industry has also been greatly improved. In the remote control room, the operator completely relies on the video images to obtain the on-site information, which requires the site-location of camera to be accurate and comprehensive. In order to improve work efficiency and reduce human participation, the image switching and the PTZ control need to be automatically controlled to adapt to the operation procedure.

FFB Characteristic

1. The automatic zooming tracking camera system which is our patent product can be installed on the proper position above the grab bucket. The most striking feature of this camera system is that the camera system always keeps tracking the grab bucket, keeps the grab bucket image in the center position of the video screen, keeps the grab bucket image occupying the appropriate proportion of the video screen, which does not move off the video screen due to the lift and move of the grab bucket.

2. The camera system can be equipped with white light or infrared light to ensure high quality image effects under low illumination conditions.

3. In view of the small space, strong vibration and heavy salt fog in the operator's cab, the Crane Special Net Video Processing Device is developed, which integrates video processing, video storage and HD decoding outputting. The Crane Special Net Video Processing Device can be installed on the side of the control console that does not affect the access of personnel, saving space. It adopts special anti-vibration treatment, 304 stainless steel enclosures, water-proof membrane technology control panel and industrial-grade keys, which are light and durable and have a long service life. The overall structure of the Crane Special Net Video Processing Device is compact, easy to install and disassemble, and the appearance is beautiful and elegant. The Crane Special Net Video Processing Device can output single screen or multi-screen.

4. According to the characteristics of the environment of the seaside and port machinery, the enclosures of camera system is suitable for environment with high pollution and high strength vibration. In order to cope with the dusty environment on site, the camera system can be equipped with a wiper device, which ensures the cleaning of the window glass.

5. The operator in operator’s cab can control the front-end camera by zooming, wiper, lighting, etc. through the control panel.

6. In order to ensure the safety of the CCTV equipments of port machinery, all camera systems are equipped with safety chains (anti-dropping).

7. Features of remote control function is that it can stably realize the automatic switching the image of each monitor along with the transformation of operation process, can stably realize the image automatic tracking, and can stably realize system status information display of the ship unloader crane etc.

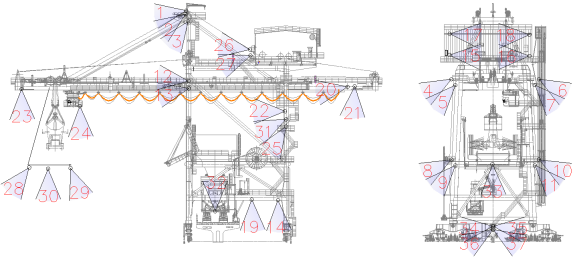

Topo Topological graph